The power battery recycling and reuse market exceeds 10 billion. Improper recycling will bring new pollution

Release time:

2018-09-14

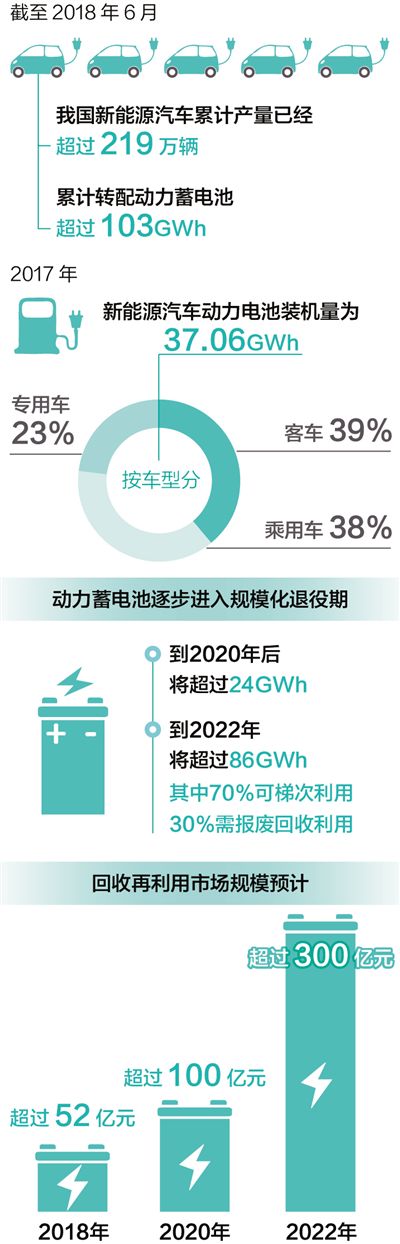

my country's new energy vehicle production and ownership have exceeded half of the global total. At the same time, new energy power batteries are entering a period of large-scale retirement, and it is expected that the cumulative retirement volume in 2020 will exceed 200,000 tons. The "Interim Measures for the Management of Recycling and Utilization of Power Batteries of New Energy Vehicles" have been officially implemented since August 1 this year. What impact will the new regulations have on the recycling of power batteries for new energy vehicles in my country? How to reasonably recycle retired batteries to prevent resource waste and environmental pollution?

Under the influence of the dual factors of policy and market environment, my country's new energy vehicle production and ownership have exceeded half of the global total. According to comprehensive calculations by industry experts from aspects such as enterprise warranty period, battery cycle life, vehicle operating conditions, etc., after 2018, my country's new energy power batteries will enter a period of large-scale retirement, and it is expected that the cumulative retirement volume in 2020 will exceed 200,000 tons. If these batteries are disposed of improperly, on the one hand, it will bring environmental impact and safety hazards to society, and on the other hand, it will also cause a waste of resources.

On July 31, the Ministry of Industry and Information Technology held a launch meeting for the national monitoring and traceability comprehensive management platform for power battery recycling of new energy vehicles. On August 1, the "Interim Measures for the Management of Recycling and Utilization of Power Batteries of New Energy Vehicles" was officially implemented, which marks that power batteries of new energy vehicles begin to accept national supervision and ensures the orderly and green development of the new energy vehicle industry.

On August 1, a publicity and implementation meeting for traceability management of new energy vehicle power battery recycling was held in Beijing. "China is the first to supervise the entire process of power batteries at the national level. This has a leading role in the development of global electric vehicles." Sun Fengchun, director of the National Engineering Laboratory for Electric Vehicles at Beijing Institute of Technology and academician of the Chinese Academy of Engineering, told reporters said during the interview.

The power battery recycling and utilization traceability comprehensive management platform is divided into a new energy vehicle on-board management module and a battery recycling management module. The former is managed by the National Engineering Laboratory of Electric Vehicles of Beijing Institute of Technology, and the latter is managed by China Automotive Technology and Research Center Co., Ltd. (hereinafter referred to as The Data Resource Center of China Automotive Industry Corporation (CATARC) is responsible for the management, mainly focusing on the echelon utilization, disassembly, and recycling of power batteries after they are retired from the vehicle. Sun Fengchun said that such whole-process management is to enable 100% traceability of each battery.

Xin Guobin, Vice Minister of the Ministry of Industry and Information Technology, introduced that the Ministry of Industry and Information Technology, together with the Ministry of Science and Technology, the Ministry of Ecology and Environment, the Ministry of Transport, the Ministry of Commerce, the State Administration for Market Regulation, and the National Energy Administration jointly issued the "Interim Measures for the Management of Recycling and Utilization of Power Batteries for New Energy Vehicles" to highlight the implementation of extended producer responsibility. System and implement the full life cycle management concept, make clear provisions on power battery recycling responsibilities, comprehensive utilization, supervision and management, etc., and build recycling and utilization around power battery design, production, sales, transportation, recycling and harmless disposal. system.

At the same time, in accordance with the principle of urgent use first, the Ministry of Industry and Information Technology, together with relevant departments, studied and proposed 16 key standards for power battery recycling. At present, four national standards for power battery product specifications and dimensions, coding rules, disassembly specifications and residual energy testing have been released. Standards for cascade utilization requirements are being submitted for approval. Three standards for battery disassembly, packaging and transportation, and material recycling have also been formed for consultation. Other standards are being developed rapidly.

17+1

Establish a recycling pilot in the form of "17 regions + 1 state-owned enterprise" to explore a resource-environment-friendly market-oriented model

Before the wave of retirement of power batteries for new energy vehicles arrives, relevant departments have started building a traceability system for power batteries from the top. Prepare for a rainy day and learn from past mistakes. "Our country has suffered losses in terms of batteries. For example, the lead-acid batteries currently widely used in various electric bicycles have had many problems in their scrapping and recycling. We are now fighting a 'blue sky defense'. If If vehicle power batteries are not managed well, it will be difficult to win this battle. Therefore, from the perspective of environmental protection and green sustainable development, the recycling and traceability of power batteries is of great significance," Sun Fengchun emphasized.

According to the "Interim Measures for the Management of Recycling and Utilization of Power Batteries of New Energy Vehicles", after August 1, the power batteries of new energy vehicles sold in the Chinese market will be included in the management, including imported new energy vehicles. According to Sun Fengchun, for domestic new energy vehicles, all models sold after 2017 have been included in the national regulatory platform for new energy vehicles. Information on models before 2017 is mostly concentrated in the hands of bus, taxi, and automobile manufacturing companies, and these companies need to manually upload relevant information to the supervision platform.

In late July, in accordance with the "New Energy Vehicle Power Battery Recycling Pilot Implementation Plan", seven departments including the Ministry of Industry and Information Technology determined that in areas with relatively concentrated new energy vehicle industry development and distinctive features, local governments will play a guiding role, with enterprises as the main body, and actively explore A market-oriented model for the recycling and utilization of used power batteries that is technically economical, resource-friendly and environmentally friendly. At present, 17 regions including Beijing, Tianjin, Hebei, Shanxi, and Shanghai and one central enterprise of China Tower Co., Ltd. have been identified as pilot projects and the pilot work has been fully launched. After the pilot period expires, the Ministry of Industry and Information Technology and other ministries and commissions will organize pilot evaluations, summarize pilot experiences, and further promote the construction of a complete, efficient, and standardized power battery recycling system nationwide.

Only companies with relevant qualifications can engage in the recycling of power batteries. According to Chen Ping, deputy director of the Data Resource Center of China Automotive Industry Center, there are more than 700 companies across the country that have been certified by the Ministry of Commerce or local commerce departments as having vehicle recycling and dismantling qualifications. Enterprises specializing in the cascade utilization and recycling of power batteries must meet the requirements stipulated in the "Industry Specification Conditions for Comprehensive Utilization of Waste Power Batteries for New Energy Vehicles".

100

The market size is expected to exceed 10 billion in 2020, and tiered utilization is promising, with applications in ancillary services and other fields.

It is predicted that the new energy vehicle power battery recycling market is huge: the market size is expected to exceed 5.2 billion yuan in 2018, to exceed 10 billion yuan in 2020, and to exceed 30 billion yuan in 2022. In other words, recycling and reusing power batteries is not only necessary for environmental protection, but also has considerable economic benefits.

The recycling and reuse of power batteries includes two links: cascade utilization and resource recovery. Usually, when the remaining capacity of the power battery on a new energy vehicle drops to 70%-80% of the initial capacity, it cannot meet the requirements of the vehicle and must be "retired". Just like a non-functioning battery on an electric toy can still be used normally in a radio, power batteries retired from cars can still be used in field electric vehicles, backup power sources, and electric energy storage after testing, screening, and reorganization. In areas where operating conditions are relatively good and battery performance requirements are low, this is echelon utilization.

The echelon utilization of power batteries is generally favored by the energy storage field. There are already echelon utilization demonstration projects operating in energy storage application fields such as large-scale renewable energy grid connection, auxiliary services, and power transmission and distribution. If the power battery cannot be used for secondary utilization, it will be dismantled to recover valuable renewable resources, such as cobalt, lithium and other metals.

There is also a lot of discussion about the economic value of dismantling and recycling power batteries. At an international energy storage summit a few months ago, Wang Zidong, director of the National 863 Electric Vehicle Major Special Power Battery Testing Center, pointed out that whether power batteries have recycling value must be determined in advance by evaluating the benefits of multi-level battery utilization. In practical applications, the recycling value of many materials is relatively low, especially the application of lightweight technology, which has led many companies to use non-metallic materials for battery box materials, and their value is even lower. For batteries such as lithium iron phosphate, the recycling value of the cathode material is not great, and recycling according to traditional processes will outweigh the gains.

"The standardized management of used power batteries of new energy vehicles after the vehicle has been retired is an important link in the traceability of the entire life cycle of power batteries. Therefore, a 'recycling management module' has been established on the national supervision platform for scrap vehicle recycling and dismantling companies and secondary utilization companies. , recycling companies complete the collection of traceability information, realize online monitoring of power batteries and implement the responsibilities of each subject," Chen Ping said in an interview.