Sewage treatment

Energy Group's wastewater treatment business covers industrial wastewater treatment, industrial park sewage treatment and domestic sewage treatment. It adopts mature sewage treatment system, sewage treatment technology and unique process combination for municipal, energy, petrochemical, chemical, textile, printing and dyeing, medicine, etc. Customers in various fields provide investment, construction and operation services for wastewater treatment projects. The Group has been deeply involved in the field of sewage treatment for many years and has rich experience in projects and is trusted and praised by customers.

Sewage treatment plant process

Improved A2/O process

The improved A2/O process combines the advantages of A2/O process and improved UCT. It has good biological nitrogen and phosphorus removal effects, and the nitrogen removal capacity is higher than that of A2/O process. It also has two processes of activated sludge process and contact oxidation. advantage. It mainly solves the shortcomings of the traditional contact oxidation high energy consumption and the contact oxidation and phosphorus removal process, maintains the high oxygen utilization rate and high biomass of the filler, has small floor space, low energy consumption, stable and reliable operation, and management. Simple, impact-resistant load and other advantages. The simplified A2/O process flow diagram is as follows:

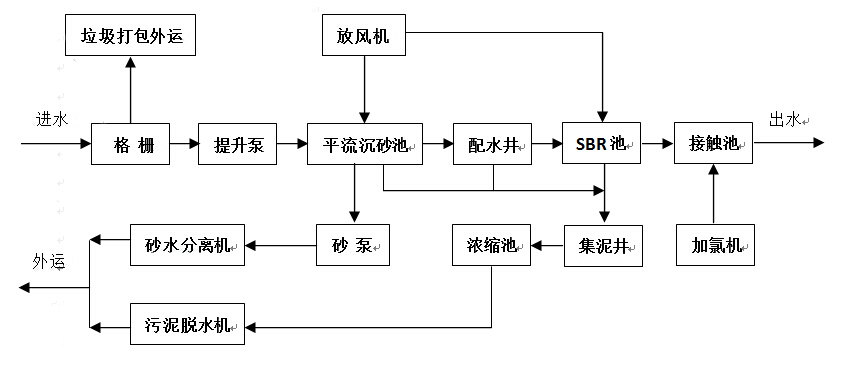

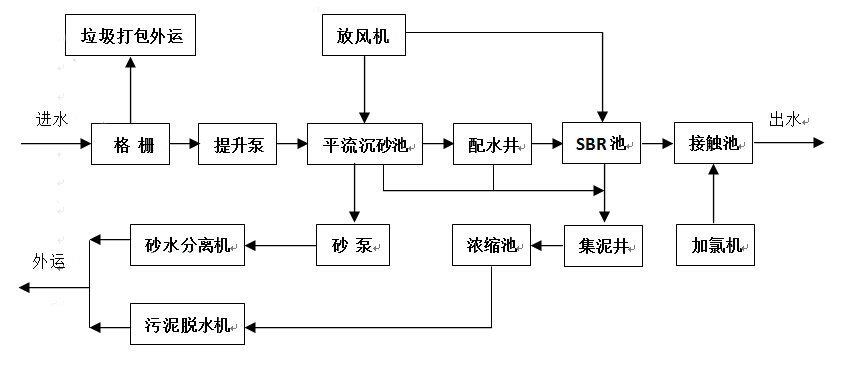

SBRProcess

The SBR process is an activated sludge wastewater treatment technology operated by intermittent aeration. It uses a time-divisional operation method instead of a spatially divided operation mode. The unsteady biochemical reaction replaces the steady-state biochemical reaction, and the ideal precipitation is placed to replace the traditional one. Dynamic precipitation. Its main feature is the orderly and intermittent operation in operation. The core of the technology is the SBR reaction tank. The pool integrates functions such as homogenization, primary sedimentation, biodegradation and secondary sedimentation in a pool without a sludge return system.

Commonly used sewage treatment methods

Waste treatment is to use physical, chemical or biological methods, or several methods to remove harmful substances in wastewater, and determine the degree of treatment according to the water quality and the direction of the treated effluent. Wastewater treatment can generally be divided into primary and secondary. And three levels of processing.

The first-stage treatment adopts physical treatment methods, that is, the use of grids, screens, sedimentation tanks, sedimentation tanks, grease traps and other structures to remove solid suspended solids and floating oil in the wastewater, and initially adjust the pH value to reduce the degree of corrosion of the wastewater. . After the primary treatment of wastewater, the discharge standard is generally not reached (the BOD removal rate is only 25-40%). Therefore, it is usually a pretreatment stage to reduce the load of subsequent processing steps and improve the treatment effect.

Secondary treatment uses biological treatment methods and certain chemical methods to remove degradable organic matter and some colloidal pollutants in wastewater. After the secondary treatment, the removal rate of BOD in the wastewater can reach 80-90%, that is, the BOD combination can be lower than 30 mg/L. After the secondary treatment, the water can generally meet the agricultural irrigation standards and wastewater discharge standards, so the secondary treatment is the main body of wastewater treatment.

However, the secondary treated water also contains a certain amount of suspended solids, dissolved organic matter that cannot be decomposed by organisms, dissolved inorganic substances, and algae-added nutrients such as nitrogen and phosphorus, and contains viruses and bacteria. Therefore, it is not possible to meet the demanding emission standards. For example, a river with a small discharge flow rate and a poor dilution capacity may cause pollution, and may not be directly used as a supply water source for tap water, industrial water, and ground water.

The tertiary treatment further removes pollutants that have not been removed by secondary treatment, such as phosphorus, nitrogen, and organic pollutants, inorganic pollutants, and pathogens that are difficult to degrade. The tertiary treatment of wastewater is based on secondary treatment, further using chemical methods (chemical oxidation, chemical precipitation, etc.), physical chemical methods (adsorption, ion exchange, membrane separation technology, etc.) to remove certain specific pollutants. Kind of "deep processing" method. Obviously, the tertiary treatment of wastewater is costly, but it can make full use of water resources.